FACT SHEET

Beef Shelf-life

Robert J. Delmore, Ph.D. | California Polytechnic State University, San Luis Obispo

Shelf-life Basics

The shelf-life of beef is of significant importance in the retail marketplace. Shelf-life is defined as the period of time between packaging of a product and its end use when product properties remain acceptable to the product user. Shelf-life properties may include appearance, texture, flavor, color and nutritive value (Singh & Singh, 2005). Simply put, shelf-life is the amount of time that passes before meat becomes unpalatable or unfit for human consumption because of the growth of spoilage organisms.

When considering the shelf-life of a meat product some people make a distinction between

case-life and shelf-life. Case-life (also referred to as color shelf-life or display-life) is

described as the length of time meat can be displayed under refrigeration before a color

change occurs. This color change from the bright, cherry-red color of beef to another color,

such as brown, is caused by a change in the protein myoglobin (Brooks, 2007). Myoglobin is

the color pigment in muscle and is responsible for binding oxygen. While this color change

is not harmful and does not denote spoilage, it results in a color customers find undesirable.

Shelf-life of beef is often used to describe the length of time before the product will spoil, or

more specifically, the time required for spoilage organisms to reach an unacceptable level.

This growth of spoilage organisms renders the product organoleptically undesirable but not

necessarily unsafe.

Confusion exists between spoilage organisms and pathogens. Acuff (2006) clarified this when describing the difference between spoilage organisms and pathogens by stating, “spoilage organisms won’t make you sick, as in instigating an infection and creating a real illness.” However, spoilage organisms make food undesirable. The meat industry works diligently to prevent, reduce and eliminate both pathogenic and spoilage bacteria before meat is delivered to consumers for purchase.

Beef is typically delivered to a retail store via two general systems: as boxed beef or in individual, case-ready packages ready for display. Boxed beef is sealed in a vacuum package and subsequently opened at retail and cut into steaks and roasts. After cutting, steaks and roasts are typically re-packaged in an oxygen-permeable overwrapped film and placed in the retail case. Individually prepared packages can be (when required) placed directly into the retail case for sale (Eilert, 2007). These two methods can involve many different packaging systems/configurations that have very different shelf-life and case-life expectations.

One of the most effective practices for improving the safety and quality of meat is proper

storage temperature (Koutsoumanis and Taoukis, 2005). Belcher (2006) describes four

criteria that dictate packaging system utilization for fresh meat delivery. The first criterion

on the list is the need to obtain the longest quality-life, which can only be achieved in

conjunction with excellent temperature control and hygiene.

Packaging Systems and their Effect on Shelf-life

Vacuum packaging - fresh

Vacuum packaging is the most common method of delivering beef primals and subprimals

throughout the beef chain. Vacuum packaging is typically accomplished through the use of a bag or pouch that has very low moisture and oxygen transmission rates. The air (oxygen

source) is removed from the package via a vacuum chamber and the package is heat sealed.

With the elimination of oxygen, the growth of typical spoilage organisms is significantly reduced, thereby extending product shelf-life. However, with vacuum packaging, myoglobin remains in the native form and has a purple color. The advent of centralized preparation of beef primal and

subprimal cuts (called case-ready) has provided a superior product with little moisture loss (shrink) and extended shelf-life. Savell et al. (1981) noted that a system involving the use of vacuum packaging for retail cuts would work well for extending retail display, but problems exist because

the color of the packaged product (purple color) differs significantly from the color expected by consumers. The shelf-life of vacuum-packaged fresh beef primals and subprimals is generally reported as approximately 35 to 45 days, with longer shelf-life of 70 to 80 days possible when

refrigeration is optimally low (28-32°F). Voges et al. (2006) reported a range of three to 83 days for average retail aging and seven to 136 days for average foodservice aging.

Vacuum packaging - frozen

There is limited literature available regarding the use and shelf-life of vacuum packaged and frozen beef. This might be because the shelf-life is very long under proper freezing temperatures and the maintenance of a good vacuum seal. From a bacterial shelf-life point of view, beef that is held below a temperature of 0°F has an indefinite shelf-life. From an optimal quality standpoint, vacuum–packaged, frozen, whole-muscle beef has a recommended shelf-life of 12 months.

Air-permeable overwrap

The most common form of fresh meat packaging in the retail marketplace is air-permeable overwrap. While this form is still utilized for the majority of the fresh beef packaged in the U.S., the number is decreasing due to the availability of modified atmosphere packaging (MAP), or case-ready systems. An air-permeable overwrap package typically consists of a foam tray and absorbent pad that rests under the meat cut. The tray is wrapped in a clear film that is permeable to moisture and oxygen. The film characteristics allow oxygen from the air to come in contact with the beef, changing the color from purple to bright cherry-red. While this package type is the most economical, it also yields the shortest case-life due to continued exposure to oxygen and the oxidation of the myoglobin, eventually resulting in a brown color (Brooks, 2007).

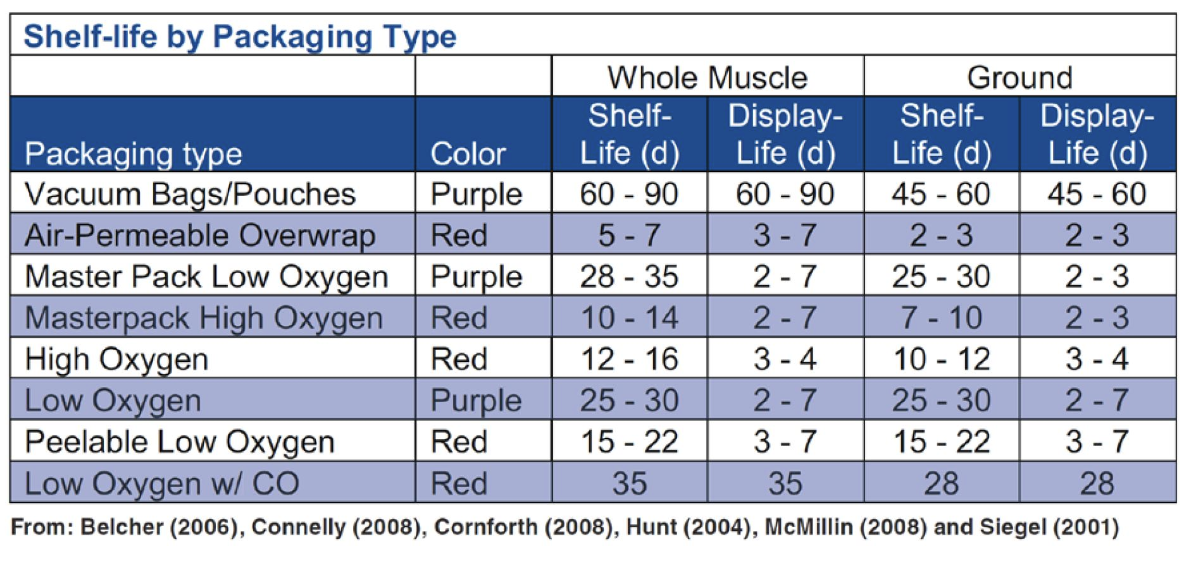

The expected shelf-life of air-permeable overwrap packages is three to seven days depending on whether the beef product is ground or whole muscle. Ground beef will a shorter expected shelf-life than whole-muscle beef.

Masterpack

The masterpack system consists of four to eight air permeable overwrapped packages that are placed in a large pouch (masterpack or motherbag) that is impermeable to oxygen and moisture. The masterpack is evacuated to remove air and then back-flushed with the desired gas mixture. Typical gas mixtures range from 100% to 80% carbon dioxide (CO2) with nitrogen (N) used as the remaining gas. The presence of CO2 inhibits the growth of bacteria and therefore extends shelf-life. When a retailer needs product to stock the shelf, he/she opens the masterpack and removes the packages from the bag with the CO2 gas blend. The product blooms in approximately 30 minutes from the atmospheric O2 it is exposed to after removal from the bag and forms the desirable, bright, cherry-red color.

The expected shelf-life of products packaged in a master pack system is ten to 14 days with a retail display-life of two to seven days.

High oxygen

High oxygen packaging systems were one of the first true modified atmosphere packages developed and remain one of the most popular. During the production of this package, a machine will vacuum residual air from the tray (rigid plastic or foam), flush the tray with a modified atmosphere and then hermetically seal the package. High oxygen MAP packages contain 80% oxygen (O2) and 20% CO2 (Belcher 2006). This high level of oxygen allows for an extended period of bloom and the CO2 prevents the growth of spoilage bacteria.

Beef packaged in a high oxygen modified atmosphere typically retains a shelf-life of ten to 14 days for ground beef and 12 to 16 days for whole-muscle beef cuts (Cornforth, 2008; Belcher, 2006).

Low oxygen N2 and CO2

Low oxygen modified atmosphere packages containing 70% N2 and 30% CO2 are used to prolong the shelf-life of fresh meat for an extended period of time. Nitrogen is an inert gas; it does not react with the meat or container and is only used to fill space. Carbon dioxide is used to prevent the growth of bacteria. The only drawback with this form of packaging is that there is no oxygen to react with myoglobin to cause blooming. When oxygen is excluded from the surface of meat, deoxymyoglobin is the predominant pigment present (Hunt 2004), resulting in a dark-purple color. U.S. consumers are not accustomed to this dark-purple color so this is a potential disadvantage of low oxygen MAP.

The expected shelf-life for beef packaged in low oxygen MAP is 25 to 35 days.

Low oxygen N2, CO2, and CO

Low oxygen MAP packages containing 69.6% N2, 30% CO2, and 0.4% carbon monoxide (CO) are used in the same way as normal low oxygen MAP. However, the CO is added because myoglobin has a high affinity for CO causing it to form the bright, cherry-red color known as bloom (Hunt 2004). This bloom color will last much longer versus in O2-rich environments because there is no free oxygen available to aid in the shift to metabolized myoglobin (metmyoglobin; brown color). One disadvantage of using CO is its negative image with the consumer as it is known as a potentially hazardous gas (Cornforth 2008). However, the concentrations that are used in MAP systems are extremely low (0.4% or lower) and do not impose any hazard to the meat or the consumer.

The expected shelf-life of low oxygen MAP with CO is approximately 28 days for ground beef and 35 days for whole-muscle beef products.

Peelable low oxygen

Peelable low oxygen trays are a normal overwrap tray with a secondary film that is impermeable to air. The tray is gas-flushed, just like a normal low oxygen MAP, before storage. Once a package is ready to be placed on display, the secondary film is peeled away allowing the product to bloom. This practice extends shelf-life because of the low oxygen environment created during storage.

The expected shelf-life for these packages is 15 to 22 days in storage. Once the secondary film is removed for retail display, shelf-life drops to three to seven days.

Conclusion

Shelf-life of beef can be extended by creating unfavorable conditions for spoilage organisms. The growth of spoilage organisms can be slowed by manipulating oxygen availability, temperature, length of storage and presence of inhibitory gasses.

References

-

Acuff, G. 2006. Thought Leader, Microbe Manager. Meatingplace, pp 28.

- Belcher, J.N. 2006. Industrial packaging developments for the global meat market. Meat Science. 74:143-148.

- Brooks, C. 2007. Beef packaging. Beef Facts, Product Enhancement. Available at: http://www.beefresearch.org/factsheets1.aspx.

- Connolly, K.B. 2008. Case-ready packaging makes its mark. Cargill Scope 1, Number 1, pp. 23-25.

- Cornforth, D. and Hunt, M. (2008). Low-oxygen packaging of fresh meat with carbon monoxide. Meat quality, microbiology, and safety. AMSA White Paper Series, Number 2, pp. 1-10. American Meat Science Association, Savoy, Illinois, USA.

- Eilert, S. 2007. Testimony before the House Agriculture Committee. Available at: agriculture.house.gov/testimony/110/ h71030/Eilert.doc.

- Hunt, M.C., Mancini, K.A., Hachmeister, K.A., Kropf, D.H., Merriman, M., DelDuca, G. and Milliken, G. 2004. Carbon monoxide in modified atmosphere packaging affects color, shelflife, and microorganisms of beef steaks and ground beef. Journal of Food Science. 69(1):45-52.

- Jeyamkondan, S., Jayas, D.S. and Holley, R. A. 2000. Review of centralized packaging systems for distribution of retail-ready meat. Journal of Food Protection. 63(6):796-804.

- Koutsoumanis, K.P. and Taoukis, P. 2005. Meat safety, refrigerated storage and transport: Modeling and management. In: J.N. Sofos, Editor, Improving the Safety of Fresh Meat. Woodhead/Publishing,

Ltd., Cambridge, UK, pp. 503–561.

- McMillin, K.W. 2008. Where is MAP Going? A review and future potential of modified atmosphere packaging for meat. Meat Science. 80(1):43-65.

- Savell, J.W., Smith, G.C., Hanna, M.O. and Vanderzant, C. 1981. Packaging of beef loin steaks in 75% O2 plus 25% CO2. I. Physical and Sensory Properties. Journal of Food Science. 44(12):923-927.

- Siegel, D.G. 2001. Case-ready concepts: packaging technologies. Western science research update conference on technologies for improving the quality and safety of case- ready products. Annual

meeting of the National Meat Association, 22 February 2001. Las Vegas, Nevada, USA. Available at: http://www.meatscience.org/ meetings/WSC/2001/default.htm> Accessed 4.04.2009.

- Singh, R.K. and Singh, N. 2005. Quality of packaged foods. In J.H. Han, Editor, Innovations in food packaging. Elsevier Academic Press, Amsterdam, pp. 22-24.

- Voges, K.L., Mason, C.L., Brooks, J.C., Delmore, R.J., Griffin, D.B., Hale, D.S., Henning, W.R., Johnson, D.D., Lorenzen, C.L., Maddock, R.J., Miller, R.K., Morgan, J.B., Baird, B.E., Gwartney, B.L. and Savell, J.W. 2007. National beef tenderness survey – 2006: Assessment of Warner–Bratzler shear and sensory panel ratings for beef from U.S. retail and foodservice establishments. Meat Science. 77(3):357-364.